by Sandy Hugill | Apr 26, 2024 | adventures, brew, columbus, ohio, tour, usa

I recently went on a tour with Columbus Brew Adventures, the premier brewery tour operator in Columbus, Ohio, USA. And while I had already been to all of the visited breweries on my own (you knew that, right?), I had a great time and learned new things. I highly recommend taking a tour.

by Sandy Hugill | Jun 6, 2019 | brewery, brewing, columbus, northhigh, ohio, usa

Occasionally, I come across a brewery with a unique hands-on opportunity. North High Brewing Co in my hometown of Columbus, Ohio, USA is one such brewery. North High opened six and a half years ago as a small, street-front brewery and taproom on High Street, the city’s primary North-South thoroughfare. It’s centrally located between the Ohio State University campus and the Short North Arts District, with lots of opportunity for drive-by and walk-in customers. It wasn’t long before North High outgrew their original space and expanded to a much larger production facility not far away. The original taproom remains a hub for craft beer drinkers, and the original brew house is a “brew your own” facility.

|

| I brewed my own beer |

Brew Day

Not yet having hands-on brewing experience, I decided that North High’s program would be the perfect way for me to get my feet wet with zero investment in home brewing equipment and supplies. I gathered my stepmom Kim and we set out to the brewery on a recent Sunday afternoon to brew our very own beer. We were greeted by James Clifford, the brewer who leads the brew-your-own program. After some quick introductions, we discussed beer styles. North High has a recipe book offering a diverse selection of brews. Knowing that we would be producing about 6 cases of beer, I wanted to pick a style that would have broad appeal. We settled on a modified IPA recipe that would be similar to a New England style: juicy and not too bitter.

|

| One of the brew-your-own groups in the brewhouse |

When James schedules individuals and groups to brew their own, he can oversee several kettles at once by staggering the brewing times of the groups. On our brew day, there were two other groups present, including one birthday party. Many of the brew-your-own participants choose this as a fun, social or team-building activity and are not interested in being 100% hands-on. Kim and I were different – we wanted to do as much as we could. Kim had some previous experience assisting my dad Steve years ago when he discovered home brewing, but I had no practical experience, and I wanted some.

While we waited for James to get our supplies ready, Kim and I enjoyed some delicious beverages from the bar. While I’m primarily a beer drinker, Kim is a vodka drinker. Neither of us was disappointed. Kim tried several vodkas from local craft distilleries, and I sampled some of the North High beers that I hadn’t tried before, including Apple Brandy Life, a sparkling ale. Apparently I was too busy working and taking pictures to keep track of the other beers I tried, but I know that in the past I’ve enjoyed their Milk Stout and Mister Fahrenheit, the New England IPA that my beer would be based on.

|

| Sampling malts |

|

| Measuring liquid malt extracts for our beer

|

|

| Kim with our pouch of milled caramel malt, or grist |

The brew-your-own program at North High offers a simplified brewing process, designed perhaps to save time and cost. Rather than making our own mash, we started with two liquid malt extracts (Pale and Pilsener) that went straight into the kettle. For good measure, James did have us mill some caramel malt, load the grist into a mesh sleeve, and dip it into the kettle to impart some of its flavor and starch. But because we didn’t create a traditional mash, there was no need for lautering, or separating liquid wort from spent grain. Instead, our malt extracts dissolved into the boil.

Dry Hop Day

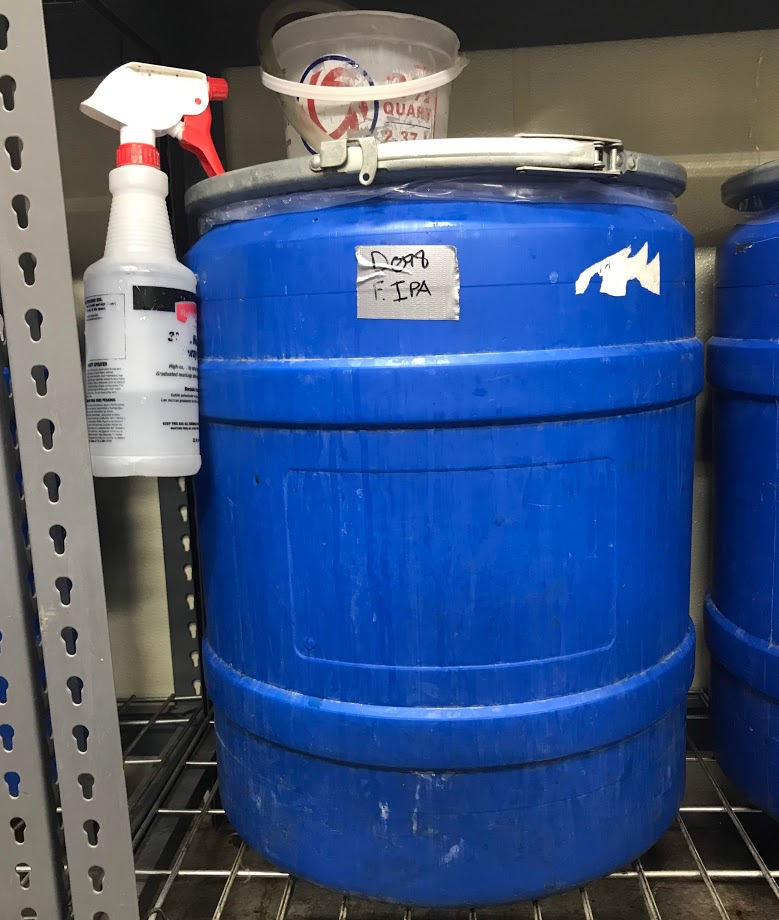

About a week later, I returned to North High to add the dry hops to my beer under James’ supervision. Typically, he manages this step for the batches that need to be dry-hopped, but I wanted to be part of it. I measured the hops, wrapped them in the mesh, and added them to the fermenting vessel quickly. The dry hops were Summit, Chinook, Centennial and Citra.

|

| Measuring the dry hops |

|

| Dry hops ready to go into the fermenter |

And while I was there, I tried the newly released North High AF American IPA, which I thought was well-balanced and refreshing. I enjoyed sitting at the bar and talking to some of the happy hour patrons. The building housing North High’s taproom was an old-time car dealership, as well as other businesses over the years. There is a lot of character to be found in the woodwork, the showroom floor (you can see where a a turntable used to display cars), and the wall of mailbox cubbies. The atmosphere feels very 1930s/1940s.

|

| You can see some of the woodworking detail from the bar; on the far side is the brew-your-own area |

|

| Drinking a North High AF American IPA on dry hop day |

Canning Day

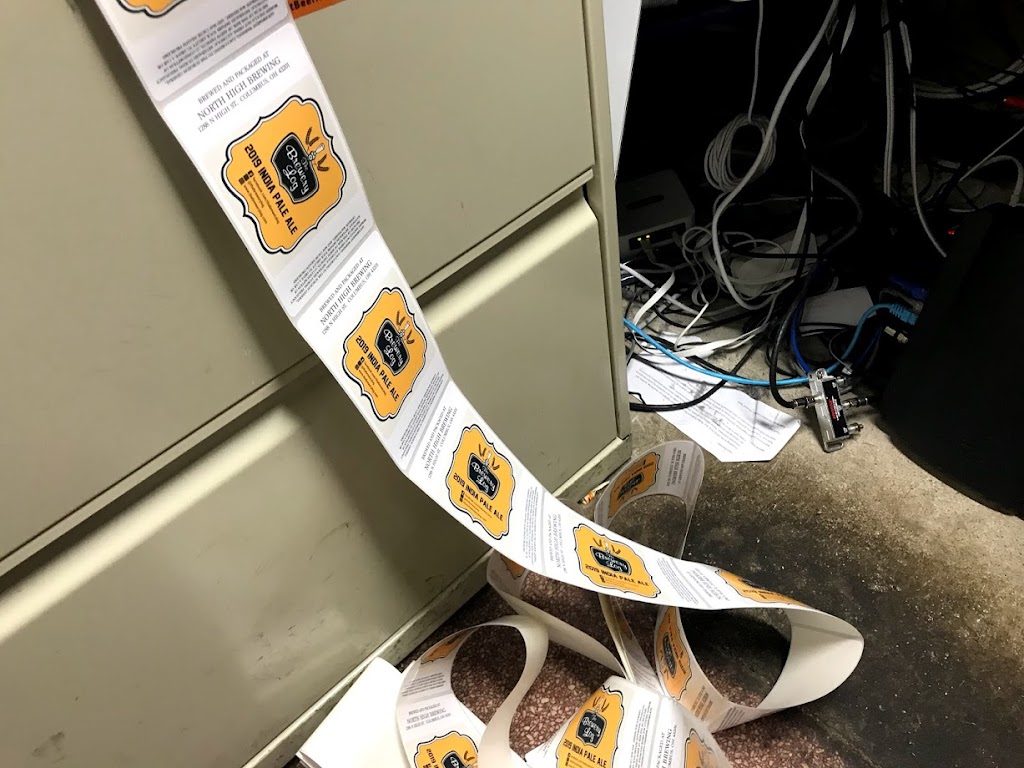

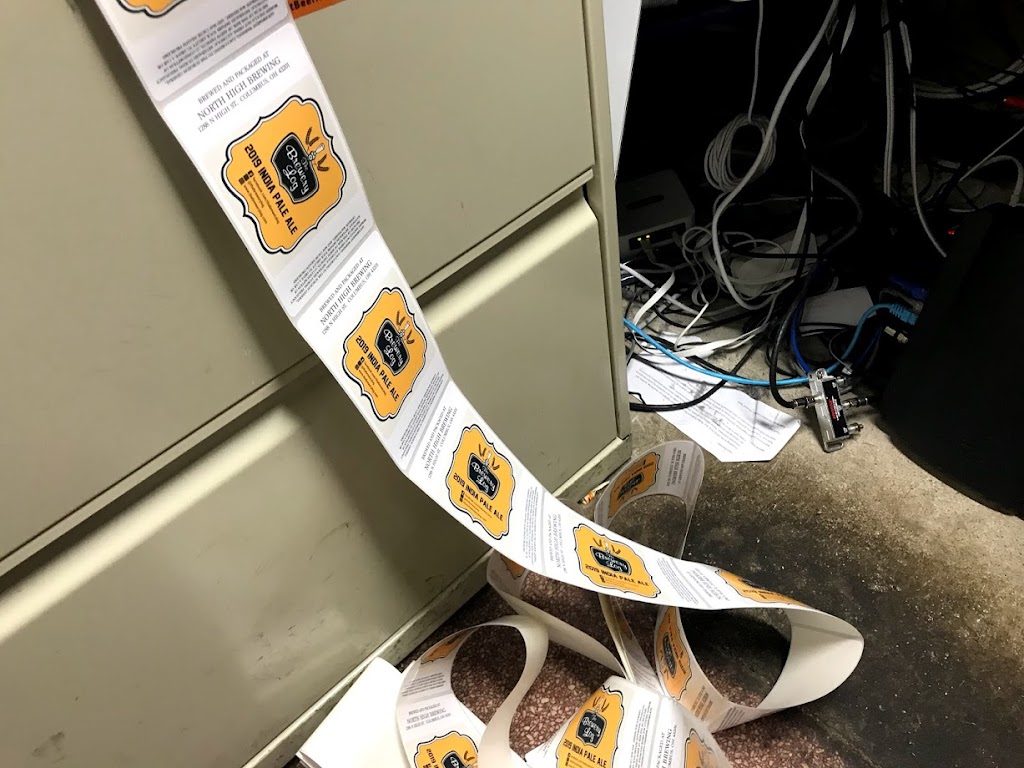

Three and a half weeks after brewing, I returned to North High to can my beer. Brew-your-own participants can choose bottles or cans as their packaging. I selected cans because they’re lighter, stack-able, air-tight and block all light from spoiling the beer. Before my canning day, I provided James with my label artwork. The brewery is required by law to label all beer that leaves the premises, but part of the label was ours to design (shout-out to my logo and beer label designer Ted Townsend). Before canning, I observed James transfer my beer from its fermenter into a keg, and then add the CO2. For canning, he hooked up a wand to the keg and the CO2 tank. The beer was fed from inside the cooler through a hose to the wand at a workstation outside the cooler.

|

| Starting my canning session with a North High Grapefruit Walleye IPA |

|

| Kegging the beer |

|

| Labels printing |

|

| First taste of my beer |

James demonstrated the proper techniques for adding first CO2 and then beer to each can, and then sealing the can. Little did I know how much time it would take to can six cases of beer by myself. Every single can had to be filled, sealed and labeled by hand. I spent a few hours at the brewery that evening, but it was worthwhile. First, I got to taste a new-to-me North High brew, Grapefruit Walleye IPA (does not contain fish), which was pretty good. And then I got to taste my own beer, which was indeed a very drinkable IPA that gave me some of the juiciness I was expecting, without too much bitterness. I also got to chat with Gavin Meyers, one of the brewery’s founders. I told him about my brew-your-own experience and he also tried my beer.

|

| Filling cans by hand |

|

| Sealing cans |

|

| Starting to stack the 6-packs |

I highly recommend going to North High if you want to try your hand at brewing, and it certainly would make a fun team-building experience for a small group. You should know that this is a streamlined brewing process, and you won’t be turned loose to do just anything that you want. There are recipes, controls and supervision in place, but these things ensure that you leave with six cases of good beer that you’ll want to drink. James is willing to work with you to help with recipe selection, and explain as much about the brewing process as you want to learn.

|

| Final product |

Now, what to do with my six cases of The Brewery Log 2019 India Pale Ale? I think I’ll plan a little can release party and invite friends and neighbors. The weather is just about right to have a little outdoor IPA tasting party one evening. I’ll distribute a few six packs to select friends and family members too. And…I’ll probably be drinking this IPA for a little while. Good thing it’s tasty!

Visit

The North High taproom is open daily. In addition to beer and spirits, you’ll find occasional food trucks, and there are many neighborhood restaurants where you can grab take-out to eat in the taproom. The brew-your-own program operates every day except Mondays and Wednesdays, and you can schedule your session online. Costs vary by beer style, but you can expect to spend about $300 total for brewing and packaging 6 cases to take home. The North High production facility is closed to the public except for special events, such as their annual anniversary party in December. Check out the brewery at

northhighbrewing.com or follow them on

Facebook,

Instagram or

Twitter.

by Sandy Hugill | Jan 16, 2019 | brewery, carroll, columbus, ohio, outerbelt, sideswipe, usa

It’s not yet open to the public, but Outerbelt Brewing Co (Carroll, Ohio, USA) is already distributing to local bars and restaurants in the greater Columbus area. I had the pleasure of previewing the brewery and taproom while still under construction. The public opening is fast approaching in the April 2019 time frame, and it will be worth the short drive from Columbus.

|

| Brewers Dan Griffin and Dom Kirchgessner |

Head brewer/minority owner Dan Griffin and brewer Dominic Kirchgessner showed me around on a recent afternoon and allowed me to taste some of their creations. Dan has been brewing professionally for several years, most recently at Gordon Biersch Columbus. Dom honed his brewing skills at Columbus’ Sideswipe Brewing Co, where I visit frequently. The connection to Sideswipe led me to check out Outerbelt.

The building is massive and 12,000 sq ft will go to the brewery, housing a 6,000 sq ft taproom, a 30 bbl brew house, special event space and a large 3+ seasons covered patio. The plan is for the bar to be full-service, and guests can dine on offerings from a variety of food trucks. It will be a fun, new brewery option in Fairfield County, which is quickly becoming a major craft beer destination.

|

| Looking toward the future brew house |

|

| When that road opens, it will lead to a bar (event space is framed in, upper right) |

|

| This old warehouse isn’t much to look at yet, but we’ll see a transformation in a couple months |

I was impressed by the beers that Dan and Dom are already brewing on their pilot 3.5 bbl system. There’s a very solid Outerbelt IPA; a hibiscus IPA called Hillbilly Knife Fight, which is a collaboration with Sideswipe; Cloverleaf, a dry Irish stout; and my favorite: Morning Commute, a brown ale brewed with local coffee.

|

| Tasting my Morning Commute coffee brown ale from the temporary kegerator |

|

| Kegging Hillbilly Knife Fight Hibiscus IPA for local distribution from the pilot system fermenters |

I’ll have additional details and photos to share about Outerbelt after their grand opening. There’s more to learn about the brewery’s backstory and the great things that Dan and Dom will be brewing up soon.

Find the Beer

Do you want to know where to find Outerbelt Brewing Co beers? Check out the brewery’s listing on Untappd. Better yet, download the Untappd app to your smartphone and discover more beers and breweries. Imagine my delight at finding Morning Commute on tap at my local neighborhood pub just a few days after visiting the brewery.

by Sandy Hugill | Dec 20, 2017 | brewery, farm, fresno, ohio, pig, usa, wooly

Another weekend, another microbrewery opening. The craft beer explosion shows no signs of slowing down as new, small breweries continue to open and fill in gaps on the map. I had the pleasure of visiting Wooly Pig Farm Brewery (Fresno, Ohio, USA) during its grand opening weekend.

|

| Kevin Ely and Jael Malenke of Wooly Pig Farm Brewery |

The Farm

Fresno, Ohio was unknown to me until I visited Wooly Pig. It’s a township east of Columbus and south of Cleveland, with a fair amount of farmland and more animals than people. And now it’s home to a farm-based craft brewery named for the fuzzy porcine residents of the farm. In fact, as I concluded my 90-minute drive from Columbus, I was greeted by the wooly (mangalitsa) pigs who were grazing in the pasture adjacent to the gravel parking lot. The pigs were curious as I walked up to the fence (it’s electric, so don’t touch!) to say hello and to photograph them. I didn’t get too close to the cute piglets, as their mothers were vocally protective of them.

|

| Wooly Pigs enjoying the sunset |

|

| Those piglets on the left? Adorable! |

My first glimpse of the farm, other than the pigs, was brief. The sun was setting and it was cold. It was not a day to explore. The brewery and a big red barn sit atop a hill, and there are trees on the property. It must be a very pretty farm come springtime. According to the Wooly Pig website, visitors will be able to tour it, to see the pigs munching on spent grain from the brewery, to meet the other animal residents, and to see what’s growing there (crops of hops perhaps, according to the farm layout on the website).

|

| The barn that will become an event venue; and that grassy area? Perfect for picnicking! |

|

| From all angles of the brewery, there’s no question of where you are |

I walked toward the red barn, which will eventually become an event space, past the pigs and down to the far end of the brewery where guests enter. There’s a nice yard, which will be perfect for picnics and beer drinking in warm weather. For the colder months, there’s a fire pit on the spacious patio, and it was in use on the frigid evening of my visit. Turning to the taproom entrance, I saw big, wide windows overlooking the barn. I found brewmaster Kevin Ely out at the fire pit and he took me inside for a tour.

|

| Brewery view from the fire pit |

The Brewery

We walked through the taproom and into the brewing space. I would wait a little while before getting to sample the beers. Kevin shared his passion for brewing German-style beers, honed through many visits to Bavaria during his time in commercial brewing. Kevin’s resume is impressive. He committed to his craft at an early age, studying biochemistry and brewing science at University of California, Davis. (Did you know that brewing could be your university major?) In his 17-year career, he worked for several breweries out west, most notably Uinta Brewing Co. in Salt Lake City.

|

| View of the brewing area from outside |

Owning his own brewery seemed to be the inevitable next step in Kevin’s career (and I’m happier for it, having enjoyed my time at Wooly Pig). The farm was a perfect place to build the brewery, as it reminded Kevin of his beloved visits to farm breweries in Bavaria, which were self-sustaining entities producing food and beer and giving back to the land. At Wooly Pig, the water used in the brewing process comes from a well on the property; it was tested for safety and flavor. The spent grain from the brewing is fed to the pigs. Eventually, mature pigs will be humanely slaughtered and used to produce sausages served in the taproom’s small kitchen. The brewery also has its own power source in the form of a hot water boiler that produces steam.

The brewing equipment was beautiful to behold. The kettles and fermenters are hand-clad in wooden planks reclaimed from demolished farm buildings or fallen trees. Kevin operates a 5-barrel system with three brewing vessels. His fermenters are 10-barrel. The brewery was designed smart, with room to expand as production grows. There’s a bottling machine, and Wooly Pig is already making brisk sales of 4-packs to go. Not just any 4-packs, but these bottles each hold 500 ml (another nod to European ways). And because Kevin focuses on German styles, there’s a lagering room in the walk-in cooler. This is where lager style beers finish their fermentation in cold storage. The process requires additional lagering tanks and more time added to the production schedule, so many small breweries only produce ales. But Kevin is a pro; he knows how to lager. I was impressed seeing this in a family-run brewery.

|

| Brewing kettles |

|

| Fermenters, each showcasing a different wood |

|

| Kevin assembled the bottling machine that packages the tasty lagers |

About the family – Kevin Ely is not in this alone. The farm is a partnership with his wife Jael Malenke, her brother Aaron and sister-in-law Lauren. Other Malenke family members play a role as well, rounding out a diverse set of credentials: scientist, farmer, veterinarian, entrepreneur, blacksmith and creative writer.

Taproom Experience

I was quite ready for some lagers after my tour with Kevin. It was early Saturday evening of opening weekend and the taproom was busy, a great sign. I waited a few minutes for a spot to open up at the bar, my preferred location for tasting beer. There were more barstools lining the picture windows and benches in the main section of the room, but I sat at the bar overlooking the action.

|

| Aaron prepares one lucky customer’s flight |

|

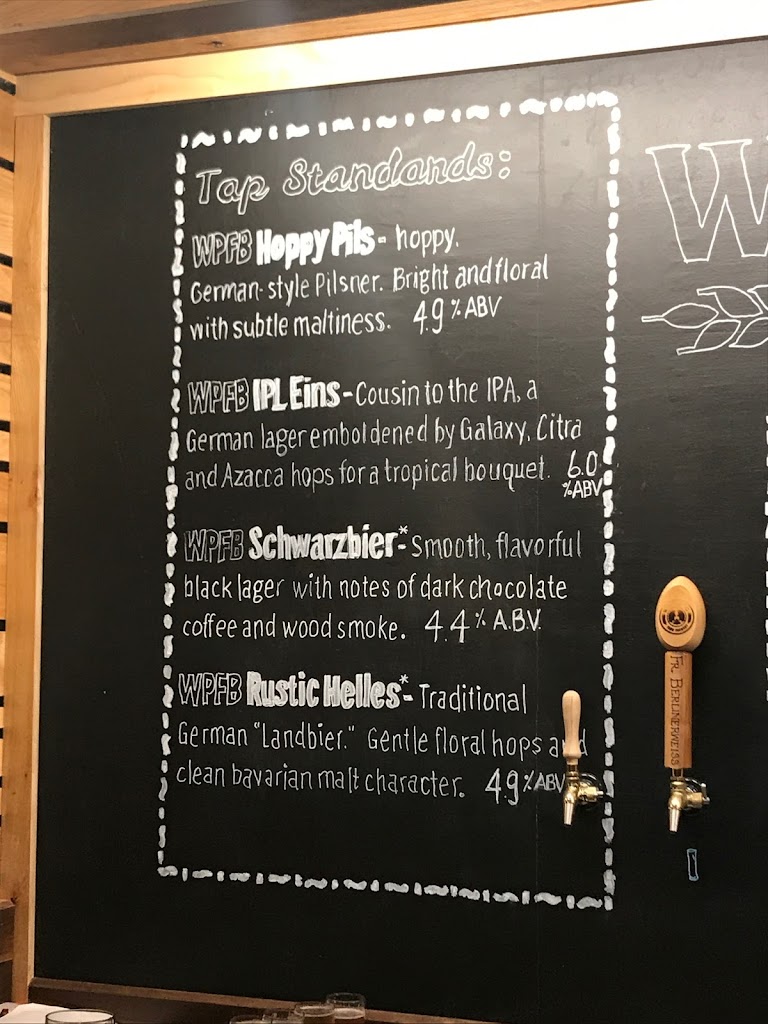

| The core beers available on my visit |

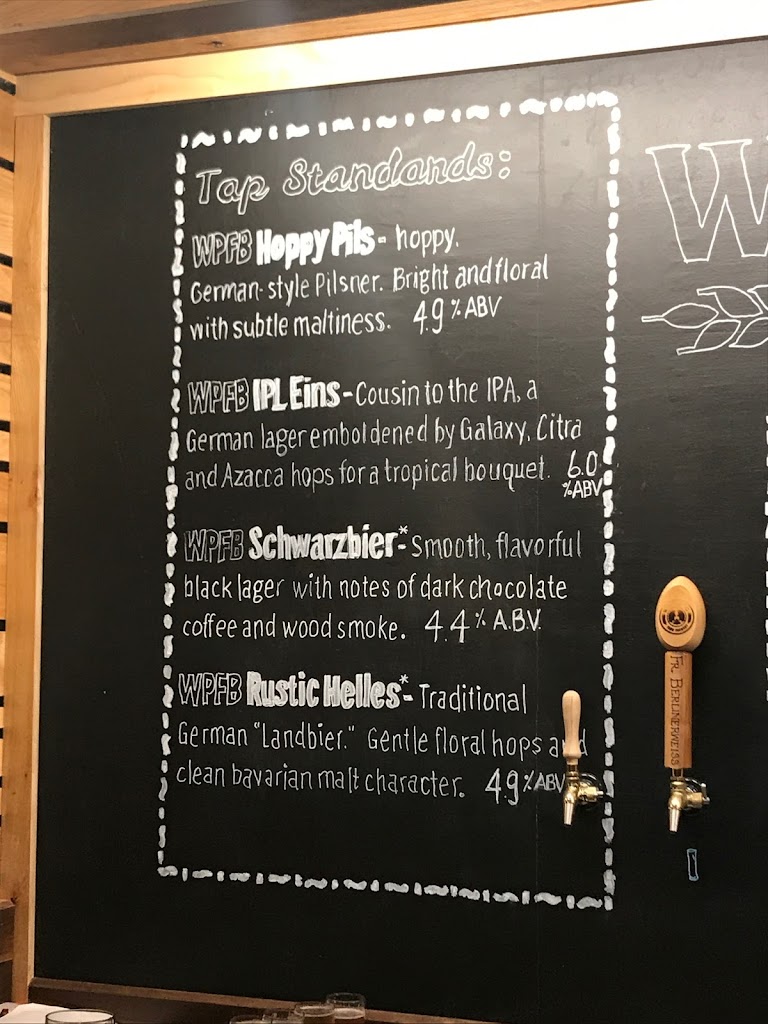

There were four core beers on the draught list, and four additional flavored beers. Flights came in samples of four or eight. I chose a flight of four and tasted a fifth:

- Hoppy Pils – a traditional pilsner

- IPL Eins – a lager nod to the ubiquitous IPA, which was dry-hopped with Galaxy, Citra and Azacca hops – this one was my favorite and I took home a 4-pack

- Schwarzbier – a traditional dark lager

- Fruited Gose – a slightly sour wheat beer, so tasty I had to take home a howler-fill

- Fruited Berlinerweiss – a wheat with passionfruit and cranberry, very festive

|

| My flight: Hoppy Pils, Fruited Gose, IPL Eins, Schwarzbier |

Though I had my favorites, all styles were well done. The beers were created by a professional brewmaster, and it was evident. They were nicely balanced and I liked the fact that they were unfiltered.

As for the taproom itself, can you say cozy? The natural wood provides a warm feel, and there are elements of hand-crafted ironwork throughout. The vibe was very welcoming, as it seemed that the entire Ely-Malenke clan was present, either working behind the bar or elsewhere, or taking a break from the busy opening weekend. They seemed to know every other visitor, so many were clearly locals.

|

| The tasting room full of happy beer drinkers |

|

| Even the barstools have wooly pigs as a foundation |

Kevin mentioned that the customers have been a mix of Fresno and other locals from neighboring towns, drive-by traffic from the well-travelled country road, and brewery tourists like me, who came from afar for the opening. Wooly Pig is definitely a destination brewery. I’ve driven farther for less atmosphere, but I’m likely to return here to experience the farm, especially in warmer weather.

The kitchen was not yet open on my visit, but Jael kept the taproom stocked with popcorn and other snacks for us to feed our appetites while drinking the delicious beers. The kitchen will open sometime in the spring. In addition to serving pork sausages, there will be menu items for vegetarian and gluten-free diets.

There’s merchandise available, and someone on my holiday list will be receiving a 4-pack and a Wooly Pig Farm Brewery mug. You can also pick up a hex sign, a t-shirt or a trucker-style hat. The gear is well-crafted, which was easy to do with such a great logo to start with.

|

| The 4-packs make beautiful and delicious gifts (via Wooly Pig Farm Brewery on Facebook) |

I spoke with Jael about Wooly Pig’s involvement in the community. They have already participated in community events such as a beer and food pairing dinner. With the Malenke family’s history and connections to the Fresno area, there will be more opportunities to engage in local and charity events as the brewery gains momentum. I’m excited to see what’s next!

Visit

Take a half-day to explore the farm, the brewery and the surrounding countryside. Prepare for a break from your smartphone (you might not have a signal in the taproom) and just enjoy being in the moment. Wooly Pig Farm Brewery is open Wednesday-Thursday 4-9 PM, Friday 4-10 PM, Saturday 1-10 PM. They sell only house beers, which can be carried out in bottle 4-packs or growlers. The farm and taproom are kid-friendly (supervised, of course). Check them out at woolypigfarmbrewery.com or follow them on Facebook and Instagram.

by Sandy Hugill | Dec 14, 2017 | brewery, brewpub, co-op, dayton, fifth, ohio, street, usa

Dayton, Ohio, USA has some breweries with unusual concepts. My next featured brewery is Fifth Street Brewpub, which operates with a co-op model. Customers do not need to join the co-op, but if they do, they become member-owners with a share of the business for only $125. My friend Shelly and I don’t live in Dayton, so we chose not to join, but we did enjoy our visit to the brewery.

|

| Fifth Street Brewpub (the smaller brew house is on the left) |

|

| You couldn’t fit many kegs in here, but it must be great for zipping around town |

Atmosphere

Driving up to Fifth Street, the brewery is easy to find. It’s a set of two green buildings on a street corner in the St. Anne’s Hill neighborhood. The main building might have been a house or a corner store when it was new; it contains the bar, the dining room and the kitchen. The smaller building is the brewhouse, and in between the two buildings is a beer garden that would have been a wonderful setting for sipping beer had the weather been warmer on our visit. It was too cold to drink outside, so Shelly and I sat down at the bar and were greeted by Mary.

|

| Not even all the taps |

The first thing I noticed was that Fifth Street has a lot of beer to choose from. There were nine or ten house taps, and a couple guest taps to fill the 12 tap system. We knew we would try a flight, but it was hard to pick just five; we ended up with an extra sampler and tried six beers total, selecting from a wide variety of beer styles. Fifth Street had a little bit of everything. Shelly’s favorites were Ludwig’s, a kölsch and Lisa’s Luck red ale. For me, it was a three-way tie between Jo Jo’s Midnight stout (with coffee notes), the Icebreaker IPA and the smooth Bière de Garde. I enjoyed being able to try the brewery’s version of popular beer styles as well as the harder-to-find styles like the saison and the bière de garde.

|

| Ludwig’s kölsch, Saison 484, Lisa’s Luck red ale, Bière de Garde, Jo Jo’s Midnight stout |

The brewpub atmosphere was rustic and cozy, with a lot of exposed wood. It was Saturday, so members and visitors were watching college football in the dining room. Because Fifth Street has a full restaurant, the brewpub is kid-friendly. We didn’t dine there, but I could have easily found something to my liking on the menu, which I would classify as elevated pub fare.

|

| The dining room |

Community Concept

Mary explained how Fifth Street Brewpub came to be only the second co-op brewery in the US. In 2010 the St. Anne’s Hill neighborhood was undergoing a revitalization and a small group of investors decided to buy the property that would later become Fifth Street. They didn’t have a business concept at the time; they just knew that they wanted to restore that property. Eventually, the idea came to launch a brewery, but to do it as a co-op. The brewpub opened in 2013 as a bar, and served their first house brews in 2014. It now has over 3,500 member-owners. Members get perks such as discounts on beer and food, birthday specials, member-only events, and the opportunity to join a home-brew competition.

|

| One of the t-shirts for sale |

|

| It’s all about community |

Fifth Street is an integral part of the community. Spent grain from the brewing process is donated to the Mission of Mary farm to be used as fertilizer. Charity involvement also includes offering local non-profits the opportunity to guest-bartend every other Sunday and on Mondays. The charity takes home a percentage of sales and all tips earned. Wednesdays are special for two reasons. This is the one day of the week that dogs are allowed on the patio for Yappy Hour. There is also a weekly Wednesday night fun run after which runners get half off a beer.

|

| The beer garden, home of Wednesday Yappy Hour |

|

| Sponsored bricks on the patio |

Toward the end of our sampler, general manager Tanya Brock arrived to tell us a little more. She said that the team at Fifth Street prides themselves on getting to know the members, and even non-member regulars by name. Shelly and I certainly felt welcome as we were given a brief tour of the brewhouse building. There is a seven barrel system with four fermenters and five brite tanks (where carbonation occurs). Members can sponsor a tank, which then bears their name. Members and guests may also purchase a brick in the beer garden for $75; many people do this as part of a special event, such as a wedding party.

|

| The separate Brew House building |

|

| Sponsored brite tanks |

Visit

Fifth Street Brewpub is open seven days a week: Sunday 10 AM to 10 PM, Monday-Thursday 4-11 PM, Friday 11 AM to 12 AM, Saturday 10 AM to 12 AM. A brunch menu is available on weekends. There are 12 taps, which are mostly filled by house beers, with a couple guest brews. Guest cans and bottles, as well as wine and cocktails are available. You can carry out a growler to enjoy the Fifth Street brews at home. Fifth Street is kid-friendly and dog-friendly during Wednesday Yappy Hour. Check them out and consider joining the co-op at fifthstreetbrewpub.coop or follow them on Facebook, Instagram and Twitter.

by Sandy Hugill | Dec 1, 2017 | brewing, dankhouse, Newark, ohio, usa

I visited DankHouse Brewing Co. (Newark, Ohio, USA) on their second weekend in business. It was a slightly chilly fall evening, and it felt prematurely dark because of the recent time change. It was a perfect situation for drinking craft beer. Newark is about an hour’s drive east of downtown Columbus, and will soon be quite a craft beer destination, with more taprooms opening soon. But DankHouse was the first Newark brewery to open to the public and they’ve got the Newark market for now.

|

| Another promising Ohio brewery |

A Family Operation

Like many of the newer nano breweries, DankHouse is a family operation. Owners Josh and Heather Lange are homebrewing hobbyists turned entrepreneurs with the opening of their new brewery. Josh is the brewmaster and DankHouse is his fulltime gig. Heather is a school teacher when she’s not at the brewery.

|

| Josh and Heather Lange, owners of DankHouse Brewing Co. |

Halfway through my customary new-brewery flight, Josh took me on a tour of the small but impressive facility. For a novice brewer, I was very impressed with everything that Josh knew. It was evident that he and Heather had done significant research before opening their business. They are doing things right.

|

| Behind the bar at DankHouse |

On the Friday night I visited, there was a vibrant crowd full of friends and family, as well as strangers (or new friends?) like me. Everyone seemed to enjoy the beer and the welcoming environment created by Heather and Josh. If this warm reception is any indication, DankHouse is going to do well in Newark.

The Property

DankHouse is a little off the beaten path if you’re not familiar with Newark, but it wasn’t hard to find. The simple, white cinder block building had a previous life housing a variety of industrial businesses. Inside, the open floor plan makes it feel larger than its square footage. The décor is clean and tasteful with pendant lamps resembling hops, fun, hand-painted mural elements, and a bar with multi-colored wooden planks featuring DankHouse-green accent boards. The bar top is stylish and is covered with BBs that Heather meticulously hand-set and covered with resin. Mood lighting creates additional ambiance. It’s an atmosphere you want to stay in and have a second beer.

|

| The cozy, friendly taproom |

|

| Fun artwork spruces up the white walls |

|

| It’s not really a hop flower, but when you’re in a brewery, these lamps feel very hoppy |

|

| Laying the BBs on the bar top (via DankHouse Brewing Co. on Facebook) |

As parents, the Langes made sure to consider their customers’ children and they built a designated play area just off the taproom, with a window cut in the wall for line of sight.

The brewing area is a couple steps down from the taproom, and a half-wall allows patrons to see the tanks. Josh operates a 2.5 barrel system, but it appears there’s room to expand if business goes well.

|

| The brewing and fermenting area, as seen looking down from the taproom |

The free-standing building sits on eight acres, which includes free parking and future space for a patio and an outdoor gaming area (think bocce and cornhole), come springtime. Behind the brewery, an extension of the Buckeye Scenic Trail is being built, so DankHouse has plans to attract cyclists and runners who need a respite once they’ve put in their mileage.

|

| It’s a fairly non-descript building, but there is magic inside |

|

| If you have a truck, you’re a real brewery |

|

| The best pic I could get at night of the patio area; come springtime, expect this place to be hoppin’ |

The Beer

I’ve discovered that these smaller breweries, at least in Ohio, start out offering more guest taps than house taps. And the reason behind this is two-fold:

- Liquor laws in Ohio won’t allow a craft brewery to begin brewing their own beer until they are open to the public*. This means that “soft openings” with guest taps are common so that a brewery has something to offer while ramping up their own production.

- Small breweries have a limited capacity for brewing. When you can only brew one beer at a time, it takes a while to get multiple styles through the brewing and fermenting process and ready for consumption.

* This may be a simplification. I am neither a brewer nor a lawyer.

Guest taps give the first customers something to drink, while giving the brewery a revenue boost. So this explains why newly-opened DankHouse had only three of their own beers on tap (and seven guest taps) when I visited. In my flight of five, I made sure to try all three house beers, while sampling a couple other new-to-me Ohio brews.

|

| Front row: Super Fantastic IPA, A Blonde Moment, Coffee Drip; back row: guest taps |

Josh plans to brew a variety of styles, and that was seen in the opening week offerings. My favorite was the Super Fantastic IPA, which was a well-balanced example of an American IPA and an excellent debut beer. Also on tap were A Blonde Moment blonde ale and Coffee Drip stout, which I would have sworn was made with actual coffee, but Josh said that all the coffee flavor came from the malt. Another IPA was in the fermenter on my visit. Maybe it’s ready to drink by now!

This little brewery is one to watch. I look forward to a return visit to see what new things Josh and Heather have in store. There will be more beers to try soon, and a whole new outdoor experience once the weather warms up.

Visit

DankHouse Brewing Co. is open five days a week: Wednesday-Friday 3-10 PM, Saturday 12-10 PM, Sunday 12-7 PM. They have 10 taps, offering a mix of house and guest beers, with growler fills available. The brewery is kid-friendly. They do not have a kitchen but will offer food trucks. You can learn more at dankhousebrewing.com or follow them on Facebook and Instagram.